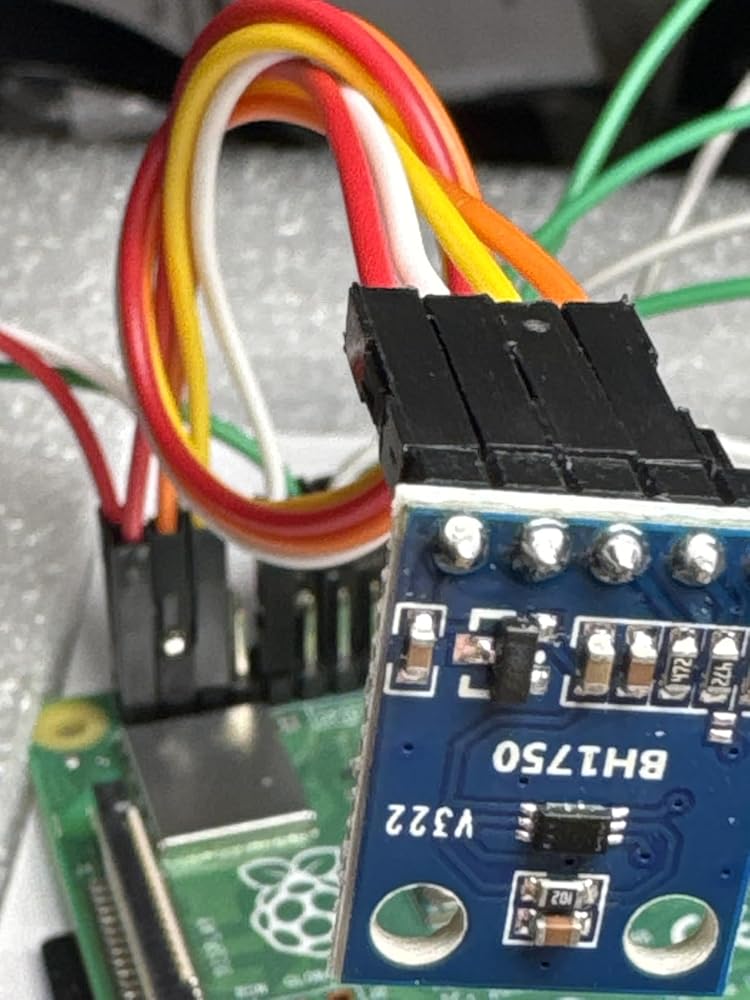

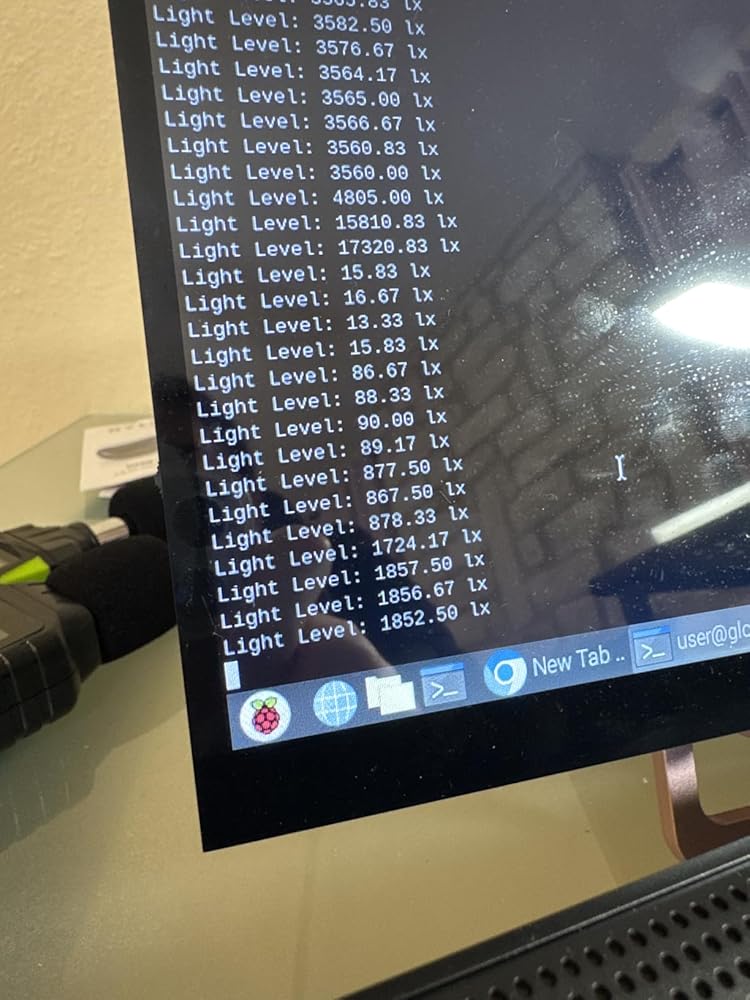

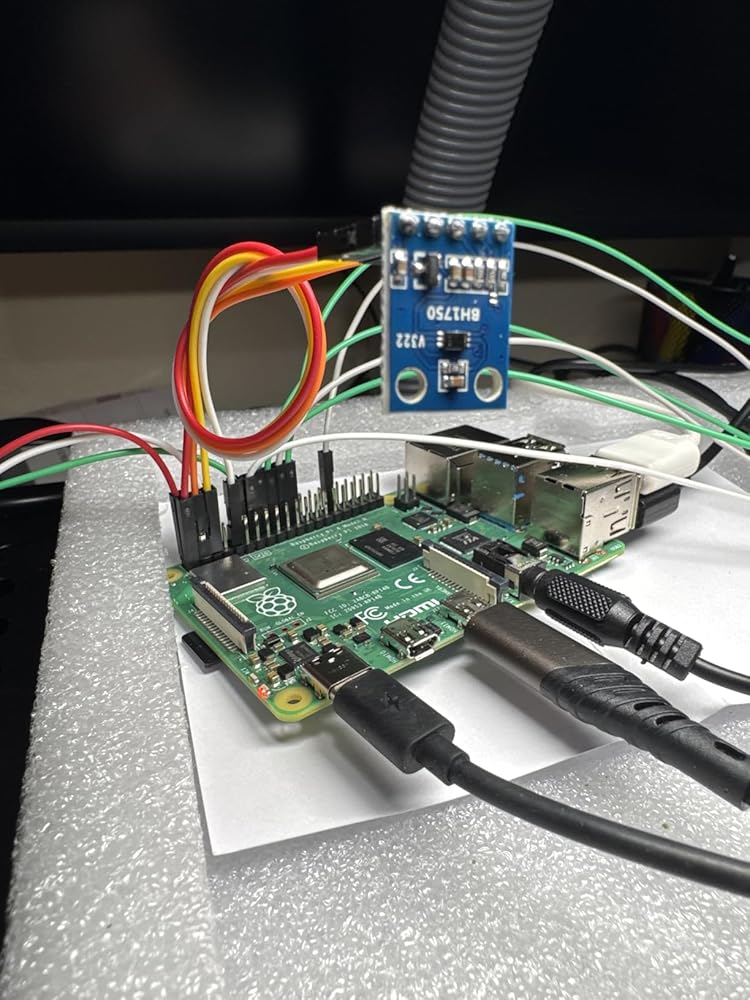

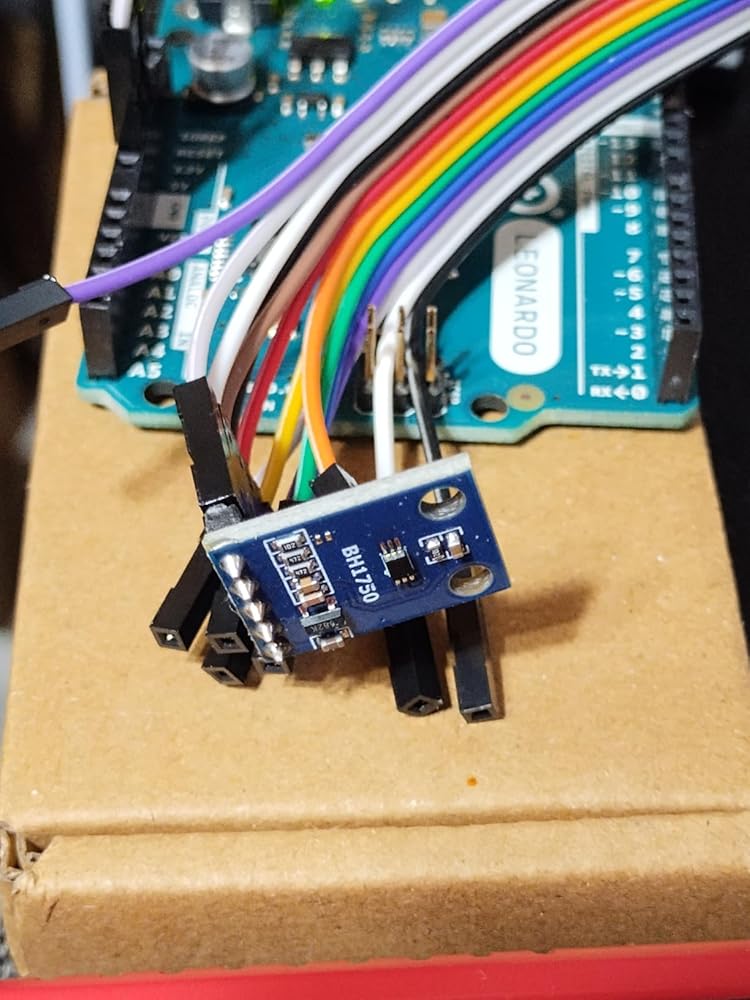

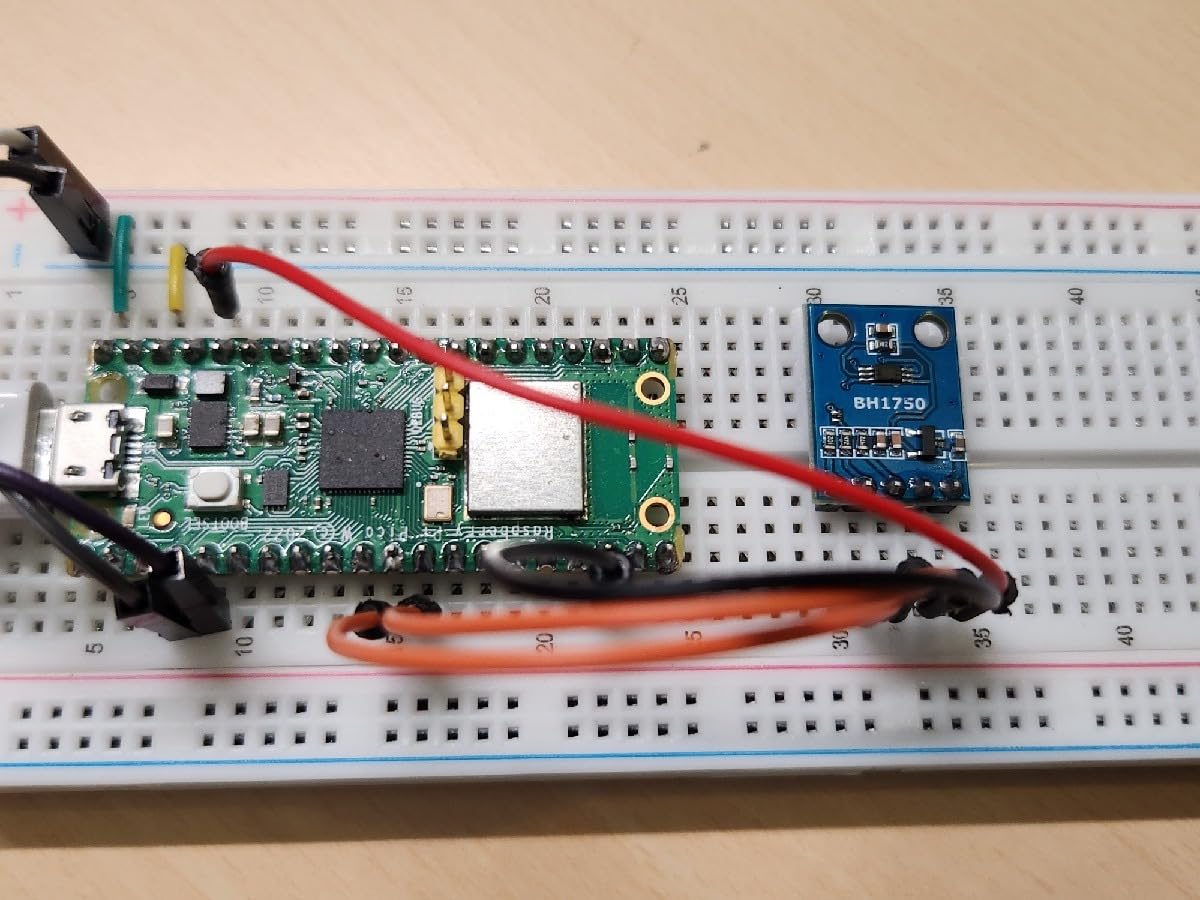

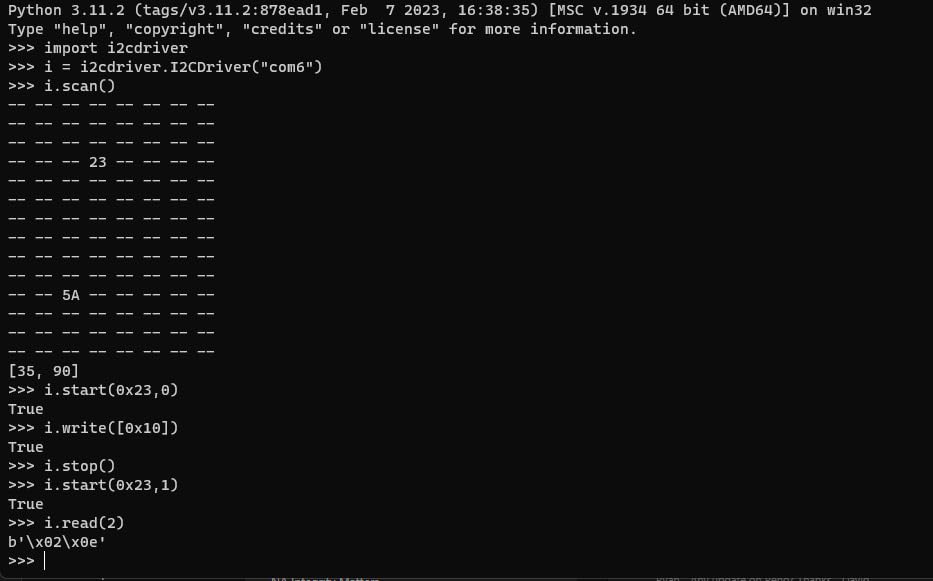

The ShillehTek BH1750 Digital Light Sensor measures ambient light intensity as a digital lux reading, making it perfect for Arduino and Raspberry Pi projects that need accurate light data without messy analog calibration. It communicates over I2C, so wiring is simple and libraries are widely available. Use it for smart lighting, automatic dimming, plant grow monitoring, daylight detection, security lighting triggers, and any build where you want consistent, real-world light measurements.

The ShillehTek BH1750 Digital Light Sensor measures ambient light intensity as a digital lux reading, making it perfect for Arduino and Raspberry Pi projects that need accurate light data without messy analog calibration. It communicates over I2C, so wiring is simple and libraries are widely available. Use it for smart lighting, automatic dimming, plant grow monitoring, daylight detection, security lighting triggers, and any build where you want consistent, real-world light measurements.

No additional feature info available.

No documents available. Please contact us for more information.

Product Overview

Product Overview

The ShillehTek BH1750 Digital Light Sensor measures ambient light intensity as a digital lux reading, making it perfect for Arduino and Raspberry Pi projects that need accurate light data without messy analog calibration. It communicates over I2C, so wiring is simple and libraries are widely available. Use it for smart lighting, automatic dimming, plant grow monitoring, daylight detection, security lighting triggers, and any build where you want consistent, real-world light measurements.